Payment Type:T/T

Incoterm:FOB

Min. Order:10 Piece/Pieces

Transportation:Ocean,Land,Air

Port:Ningbo

$1- /Piece/Pieces

Model No.: Alu-3

Brand: Ration

Place Of Origin: China

Type: customize

Material: Alumimum

Tolerance: 0.01mm

Type Of Machining: Milling and turning

Packaging: Anti-rust bag,Cardboard box, Euro pallet

Productivity: 1000000000 pcs

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 1000000000 pcs

Certificate: TUV

HS Code: 8207300020

Port: Ningbo

Payment Type: T/T

Incoterm: FOB

The process of CNC Machining of aluminum alloys is generally carried out by CNC machining centers (3 axes, 4 axes and 5 axes) / engraving machines on aluminum materials (6061, 6063, 7075 and other materials). Many products will require subsequent surface processing, such as sandblasting. Anodizing treatment / surface powder spraying / electrophoresis, etc.

| Geometric Tolerance | Location Degree | Parallelism | Concentricity | Verticality | Beating Of All | Symmetry | Flatness | Cylindricity | Roundness | Roughness |

| Measurement Accuracy(mm) | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | Ra0.01 |

| Machining Accuracy(mm) | 0.03 | 0.005 | 0.005 | 0.01 | 0.01 | 0.01 | 0.002 | 0.01 | 0.005 | Ra0.4 |

Our Service

Scope of service: processing according to drawings

Service items: Cnc Processing, Metal Processing Service, mass production, rapid sample, non-standard hardware parts customization

Processing technology: CNC machining, turning, drilling, chamfering, tapping, steel plate knurling, cold steel, stamping, die-casting, wire cutting, etc.

Processing materials: aluminum, iron, stainless steel, copper, etc. grinding, polishing, electroplating and silk screen printing, cobaltization, blackening laser, heat treatment, etc.

Surface treatment: anti-dropping glue, surface rust pattern anodizing, etc.

Applicable industries: CNC processing and production experience in communication equipment, household goods, electrical components, automobiles and motorcycles, agricultural components, etc.

Service features: fast processing speed, high precision, tolerance up to 0.01MM.

Our Advantages

Fast delivery

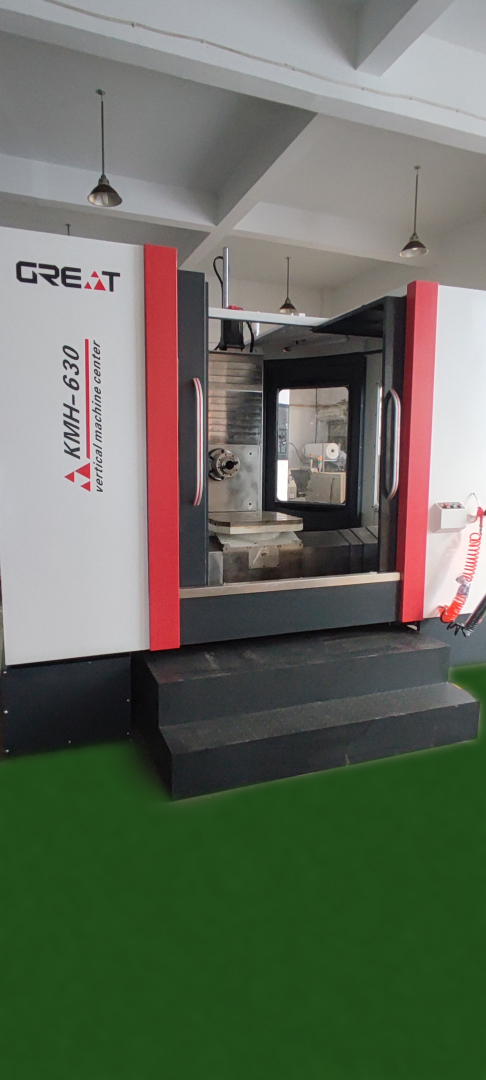

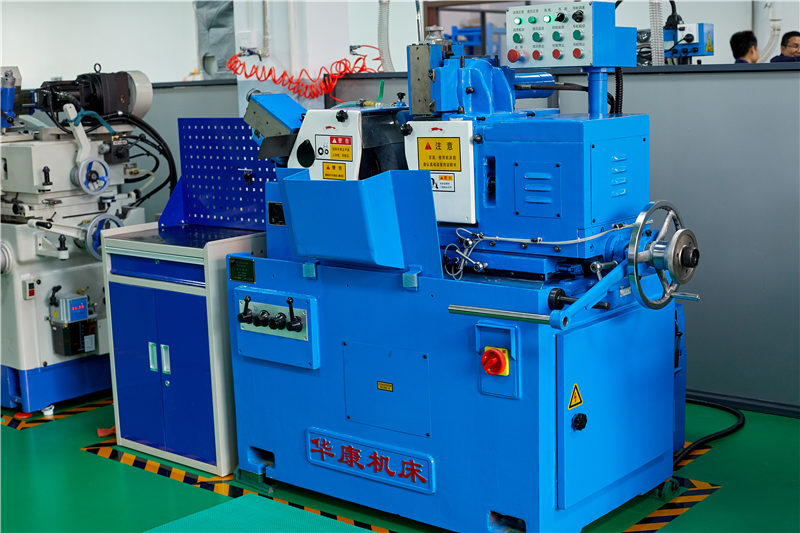

1 hour on the machine, special follow-up, 8 large and small machining centers, 20 CNC lathes, rich experience and large production capacity. Rapid production within 10 days is possible.

High precision

The tolerance can be controlled within ±0.01mm.

Quality control

TUV and ISO9001 quality system, quality assurance department implements strict quality assurance process, process inspection, inspection before delivery.

Our Equipment